Pinoproseso ng end mill ang stainless steel at heat-resistant alloys-T503

Mga bentahe ng produkto

Ang mataas na matigas na bakal ay isang medyo mahirap na materyal na iproseso, ang HRC ay karaniwang nasa itaas ng 50 degrees, ang ilan ay may higit sa 60 degrees, upang pumili ng isang mahusay na patong at materyal, kontrolin ang lakas ng tip ng tool, upang mas maprotektahan ang tooll.

Ang end milling cutter ay gumagana ng mataas na tigas na bakal

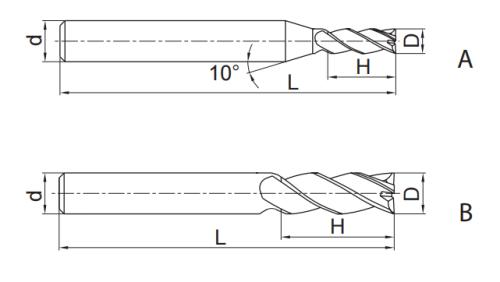

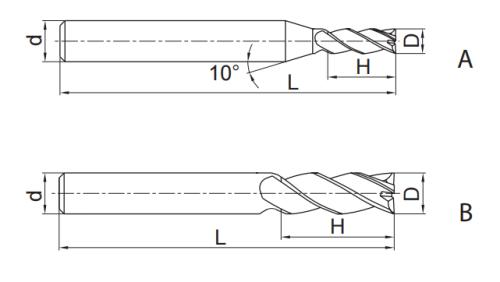

| Pagtatalaga | D | d | H | L | Z | Fig. |

| HE-Z-D1.0S | 1.0 | 4 | 3 | 50 | 2/4 | A |

| HE-Z-D1.5S | 1.5 | 4 | 4 | 50 | 2/4 | A |

| HE-Z-D2.0S | 2.0 | 4 | 6 | 50 | 2/4 | A |

| HE-Z-D2.5S | 2.5 | 4 | 8 | 50 | 2/4 | A |

| HE-Z-D3.0S | 3.0 | 4 | 8 | 50 | 2/4 | A |

| HE-Z-D4.0S | 4.0 | 4 | 11 | 50 | 2/4 | B |

| HE-Z-D1.0 | 1.0 | 6 | 3 | 50 | 2/4 | A |

| HE-Z-D1.5 | 1.5 | 6 | 4 | 50 | 2/4 | A |

| HE-Z-D2.0 | 2.0 | 6 | 6 | 50 | 2/4 | A |

| HE-Z-D2.5 | 2.5 | 6 | 8 | 50 | 2/4 | A |

| HE-Z-D3.0 | 3.0 | 6 | 8 | 50 | 2/4 | A |

| HE-Z-D3.5 | 3.5 | 6 | 10 | 50 | 2/4 | A |

| HE-Z-D4.0 | 4.0 | 6 | 11 | 50 | 2/4 | A |

| HE-Z-D4.5 | 4.5 | 6 | 11 | 50 | 2/4 | A |

| HE-Z-D5.0 | 5.0 | 6 | 13 | 50 | 2/4 | A |

| HE-Z-D5.5 | 5.5 | 6 | 16 | 50 | 2/4 | A |

| HE-Z-D6.0 | 6.0 | 6 | 16 | 50 | 2/4/6 | B |

| HE-Z-D8.0 | 8.0 | 8 | 20 | 60 | 2/4/6 | B |

| HE-Z-D9.0 | 9.0 | 10 | 22 | 75 | 2/4/6 | A |

| HE-Z-D10 | 10.0 | 10 | 25 | 75 | 2/4/6 | B |

| HE-Z-D12 | 12.0 | 12 | 30 | 75 | 2/4/6 | B |

| HE-Z-D14 | 14.0 | 14 | 32 | 75 | 2/4/6 | B |

| HE-Z-D16 | 16.0 | 16 | 45 | 100 | 2/4/6 | B |

| HE-Z-D18 | 18.0 | 18 | 45 | 100 | 2/4/6 | B |

| HE-Z-D20 | 20.0 | 20 | 45 | 100 | 2/4/6 | B |

Universal end mill para sa steel cast iron

| Pagtatalaga | D | d | H | L | Z | Fig. |

| HE-ZL-D3.0 | 3.0 | 6 | 12 | 75 | 2/4 | A |

| HE-ZL-D4 | 4 | 6 | 15 | 75 | 2/4 | A |

| HE-ZL-D5 | 5 | 6 | 20 | 75 | 2/4 | A |

| HE-ZL-D6 | 6 | 6 | 20 | 75 | 2/4/6 | B |

| HE-ZL-D8 | 8 | 8 | 25 | 100 | 2/4/6 | B |

| HE-ZL-D10 | 10 | 10 | 30 | 100 | 2/4/6 | B |

| HE-ZL-D12 | 12 | 12 | 35 | 100 | 2/4/6 | B |

| HE-ZL-D14 | 14 | 14 | 40 | 100 | 2/4/6 | B |

| HE-ZL-D16 | 16 | 16 | 50 | 150 | 2/4/6 | B |

| HE-ZL-D20 | 20 | 20 | 55 | 150 | 2/4/6 | B |